Melamine Plywood For Decoration

Why Choose Melamine?

As mentioned previously, melamine is most commonly used in the furniture industry because of its resistance to heat, moisture and scratches. Besides that, some of the reasons to consider melamine include:

Easy to clean and maintain

Crack-resistant

Durable

Budget-friendly

Consistent grains

Available in a range of thickness

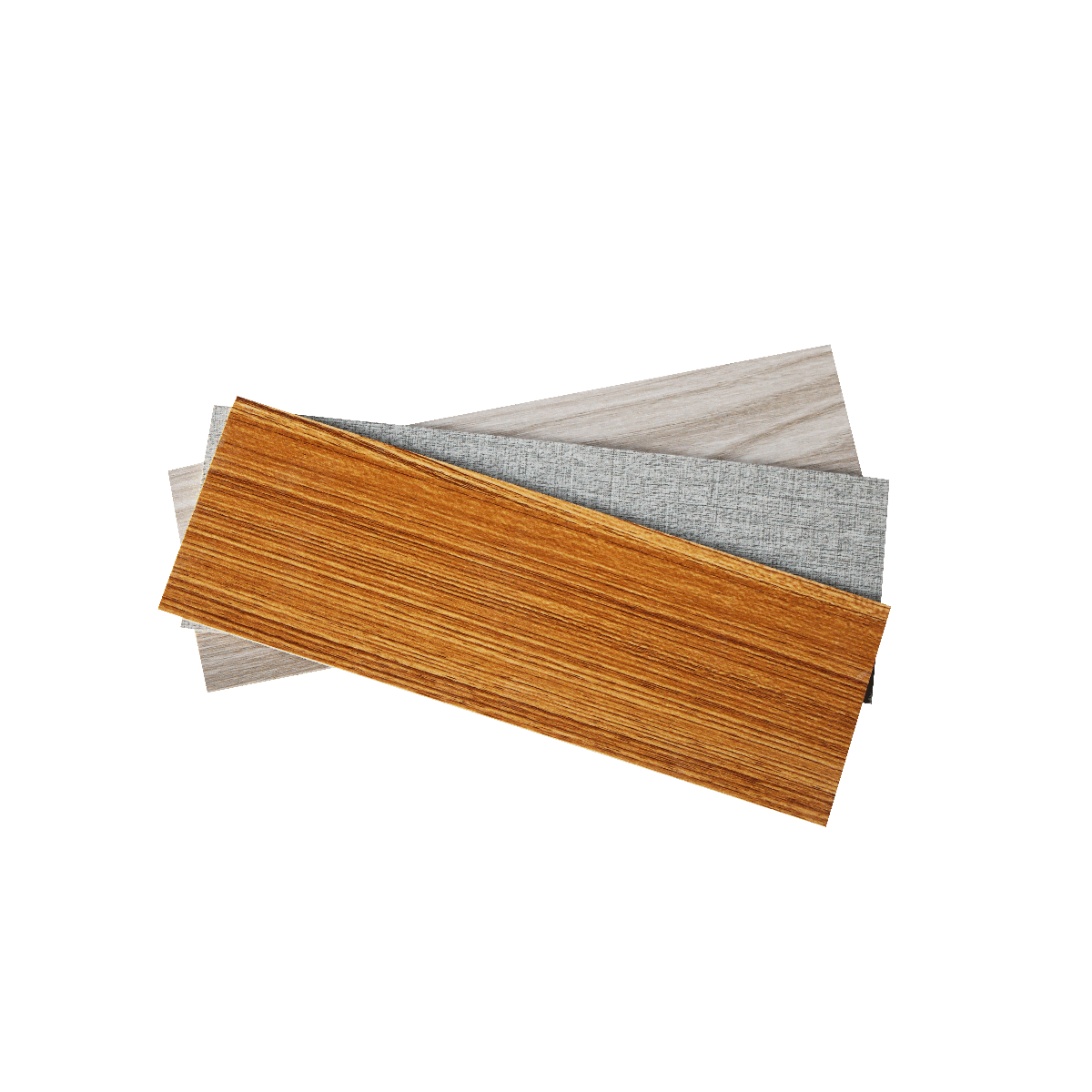

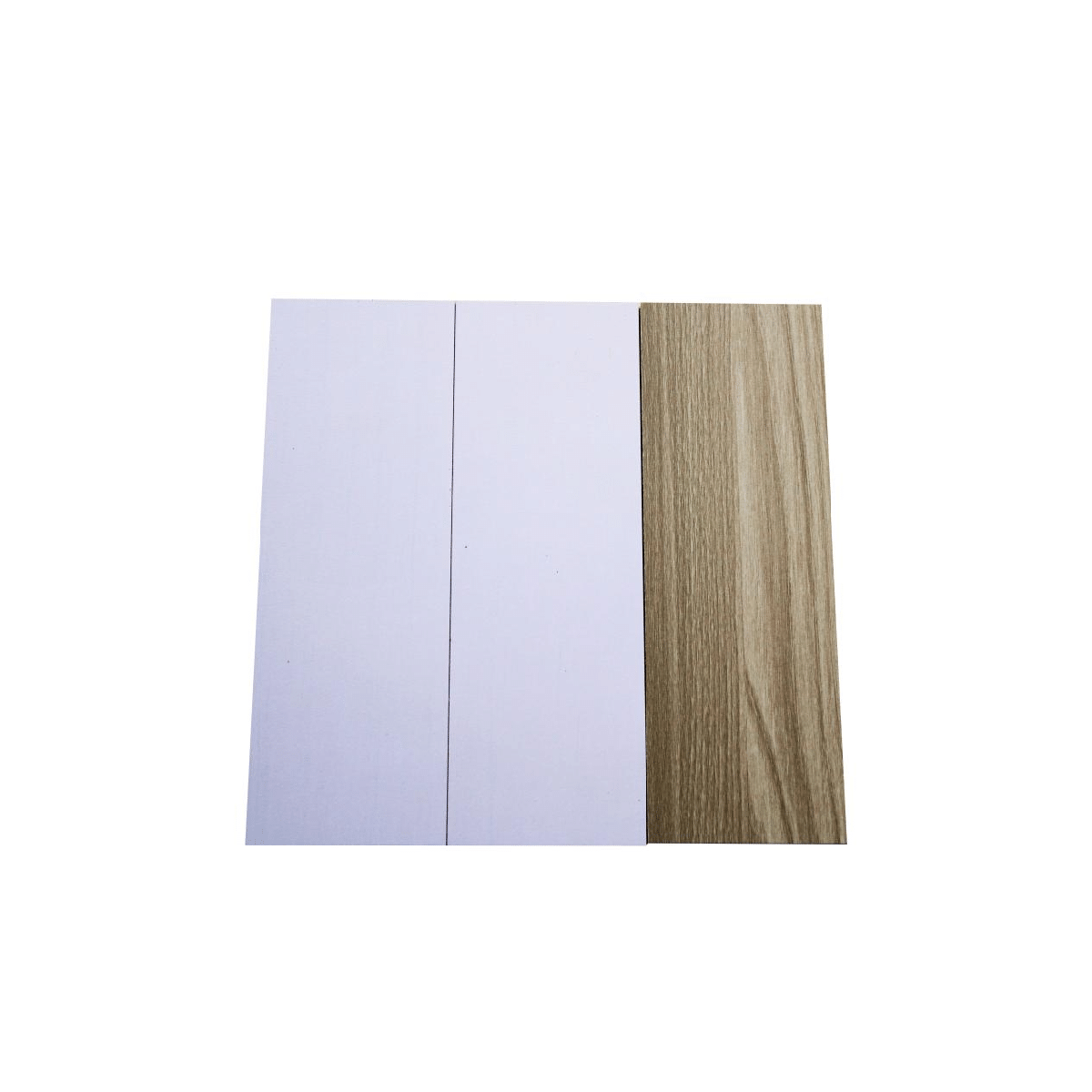

We have melamine panels in all the common colors, White, ware white, Black, Almond, Grey, Hardrock Maple and wood grains.

These type of Panels are commonly used in furniture and cabinets as they are highly resistant to moisture, stain, soiling and scuffing and have superior durability and wear resistance. Consequently, many garage workshops have Melamine panel cabinets which are also found in many kitchens, bathrooms, inside closet storage areas and other high profile applications that require strong scratch resistance. Many panels are used for desks, shelves, cabinets and in other places in large Health Maintenance Organizations.

Advantages of Melamine

When considering whether or not melamine board is a good option, you of course want to know the advantages. Melamine has several:

Durability – Melamine is highly durable, scratch-resistant, waterproof, stain-resistant, and easy to clean (bonus!).

Perfect finish – Melamine is available in a wide selection of textures and natural wood grains, and melamine panels are a cost-effective, multipurpose option for adding color, texture, and finishes to designs and projects.

Budget-friendly – Melamine board is a budget-friendly option without sacrificing quality and durability. It can save money and time during application because there is no need to sand or finish as with solid wood.

We are exporting our full poplar core film faced plywoods to a lot of places and countries, in Africa and West Asia,they call our plywood as the marine plywood ,because our plywood is waterproof for construction. In South Asia ,Philippines , people call our film faced plywood as the phenolic plywood, and also some clients from Europe and Canada call them the shutter formwork etc, anyway if you are looking for the construction plywood for the formwork usage ,I can tell that you find the right product and the right company ,please check our following details and contact us if you need some boards,we muse offer you the good quality and good price.